Challenges of the brick industry in India

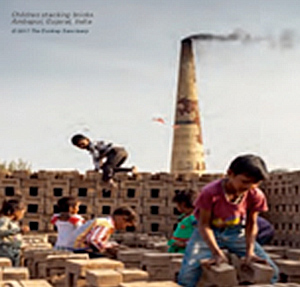

India's CO2 emissions are about 2.2 billion tons, which is the third largest CO2 emitting country in the world after China and the United States. It is attracting international attention for its reduction of 1 billion tons of CO2 emissions by the year and the announcement of the goal of zero net emissions by 2070. Focusing on the field of construction materials in India, the CO2 emissions associated with the production of "fired bricks", India's main building material, are estimated to be about 100 million tons/year, which is about 5 for India as a whole. It occupies a large proportion of%. In addition, since fired bricks are made from clay, about 700,000 ha/year of agricultural land has been scraped off for brick production, and the rapid decrease in agricultural land and the deterioration of wasteland have become serious problems (Photo 1). ing. Furthermore, in the brick industry, human rights issues have been pointed out internationally because poor workers, including women and children, are engaged in manufacturing in dangerous and unsanitary working environments (photo). 2).

-

Photo 1) Agricultural land scraping

-

Photo 2) Brick kiln and child labor

Outline of research on unfired bricks and cooperation with local companies

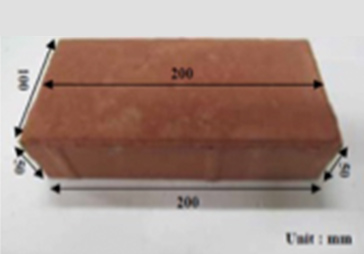

Aiming to solve the above-mentioned problems, we started research on "non-fired bricks (= non-fired bricks)" in 2008, and during the research period of 10 years or more, with the cooperation of local companies that have block factories. Originally, there is a history of conducting research, and it can be said that this is an example of SDGs contribution technology originating from the local area. An example of unfired brick developed with the cooperation of a local company (Photo 3) is shown.

- (1)Features in terms of raw materials

- While general fired bricks use clay as the main raw material, unfired bricks do not use any clay as a raw material, and about 40% of the total mass is coal, which is waste derived from coal-fired power generation. Ash (hereinafter referred to as fly ash) occupies the raw material composition with consideration for the environment.

- (2)Manufacturing Characteristics

-

Literally, non-firing bricks are a manufacturing method that does not require firing, and because they use a pressing device (example: Photo 4), they consume some power, but compared to firing. CO2 emissions in the manufacturing process are overwhelmingly low. On the other hand, in terms of productivity, it is estimated that the productivity is more than five times that of fired bricks, so it is a mass production technology that can sufficiently meet the brick market, where demand will continue to grow in the future.

Photo 4) Prototype of press equipment and non-fired brick (solid version) owned by a local company - (3)Manufacturing Characteristics

- The most important quality item for bricks is compressive strength, which is also related to market pricing. The higher the compressive strength, the higher the market price. Similar to JIS applied in Japan, a standard called IS (Indian Standard 1077: Common Burnt Clay Building Bricks) is set in India, and 7N/ mm2 is set as the specified value for the compressive strength of bricks... As a result of research so far, it is possible to develop a compressive strength of 15 to 20 N/mm2 at the same price as conventional fired bricks, which is about 2 to 3 times the Indian standard. As mentioned above, it is also excellent in cost performance, so it can be expected to develop new applications other than conventional applications.

Local non-fired brick technology and SDGs contribution

SDGs presented by unfired bricks

-

Contributed bydeveloping low-carbon technology

-

Contributed by the material composition of unused clay

-

Contributed by recycling coal ash

-

Contributed by a hygienic working environment and high production method

-

Contribution through efforts between Japan and India and collaboration with local companies

【Reference】

- 1)https://cdn.cseindia.org/docs/aad2015/11.03.2015%20Brick%20Presentation.pdf

- 2)Internal Labour Organization: Environment, human labour & animal welfare, Unveiling the full picture of South Asia’s brick kiln industry and building the blocks for change, 2017, https://www.ilo.org/global/topics/forced-labour/publications/WCMS_542925/lang--en/index.htm